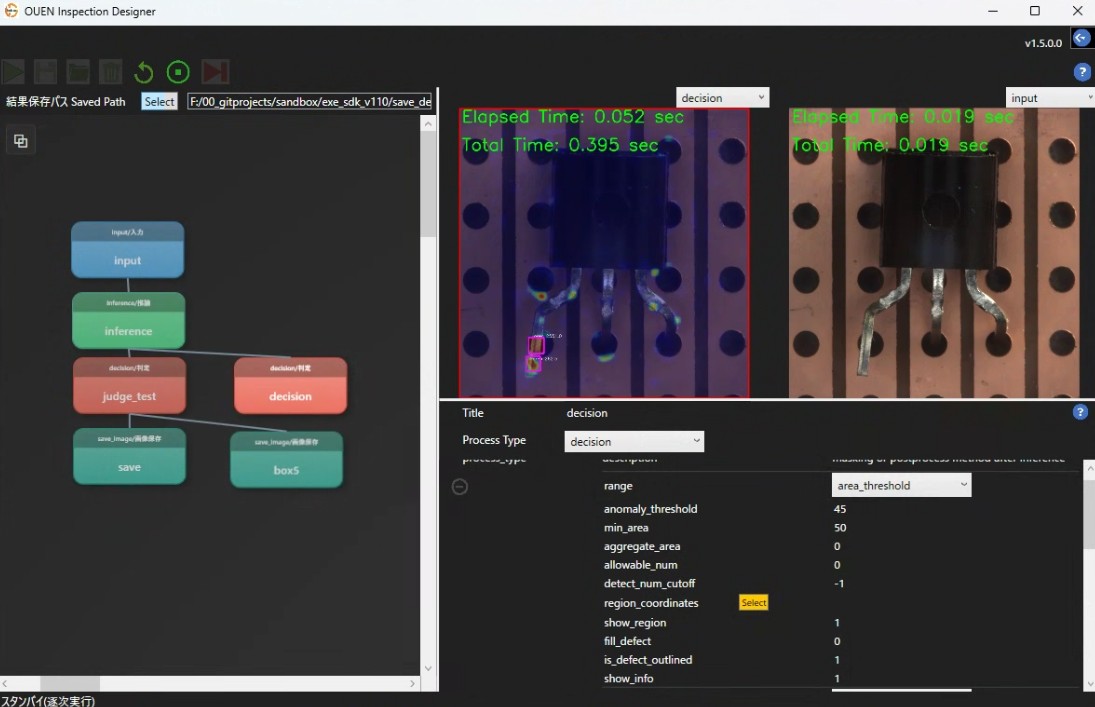

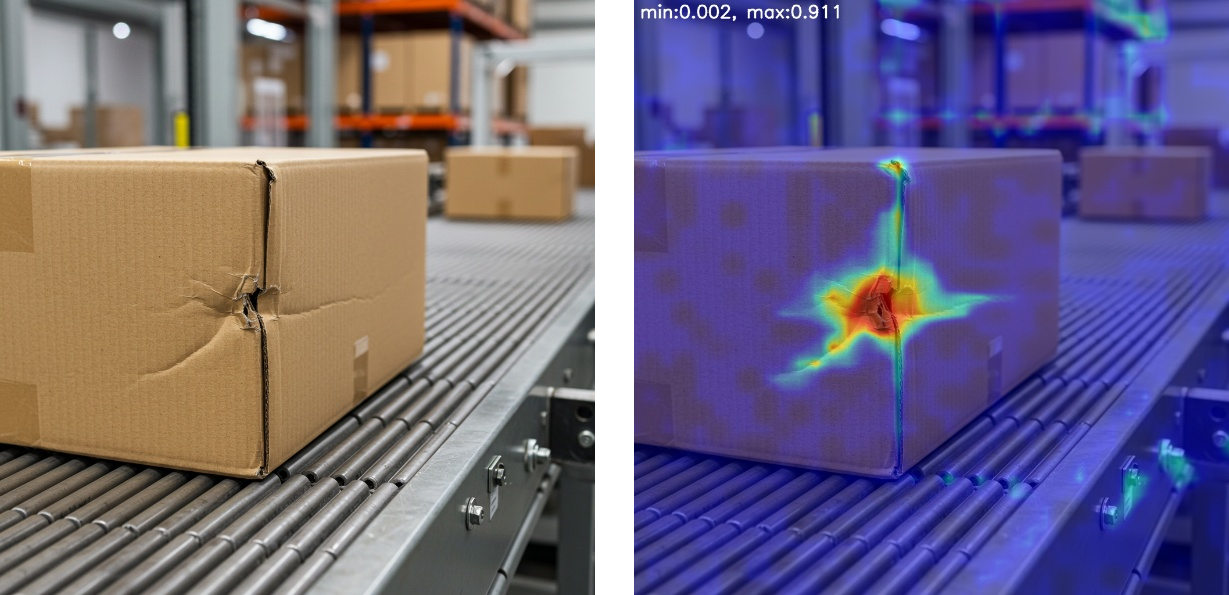

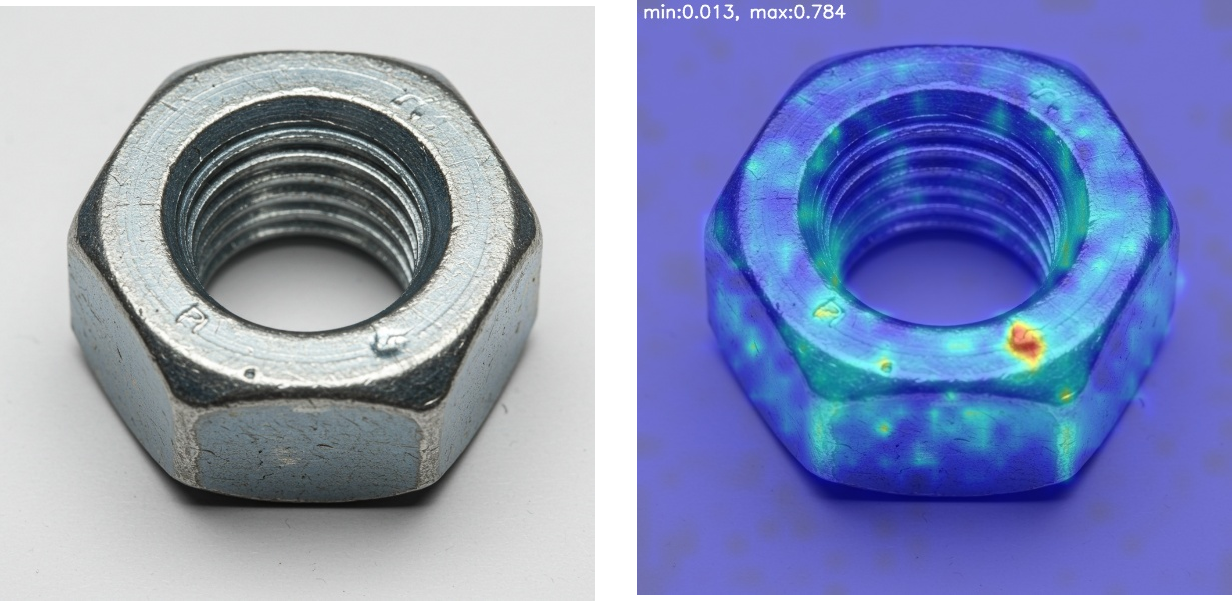

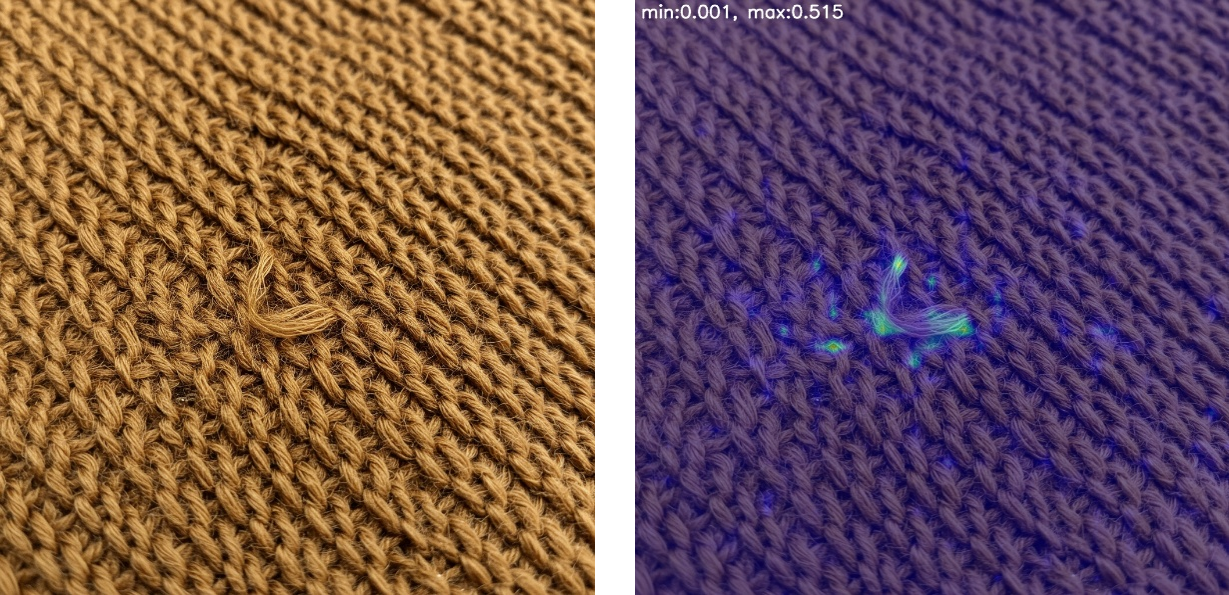

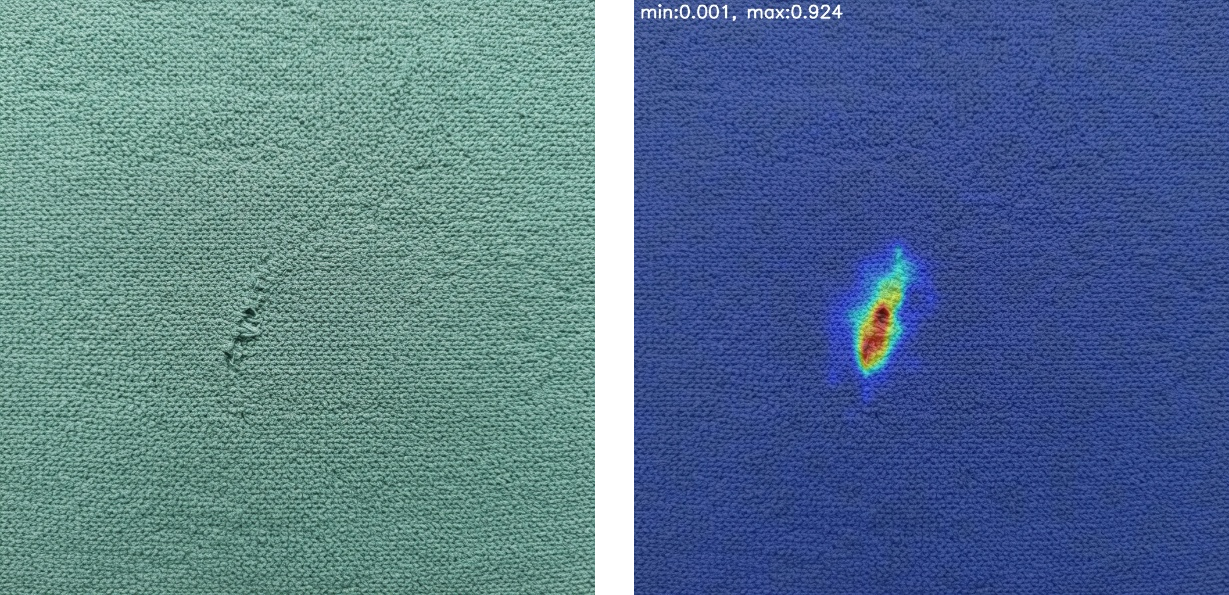

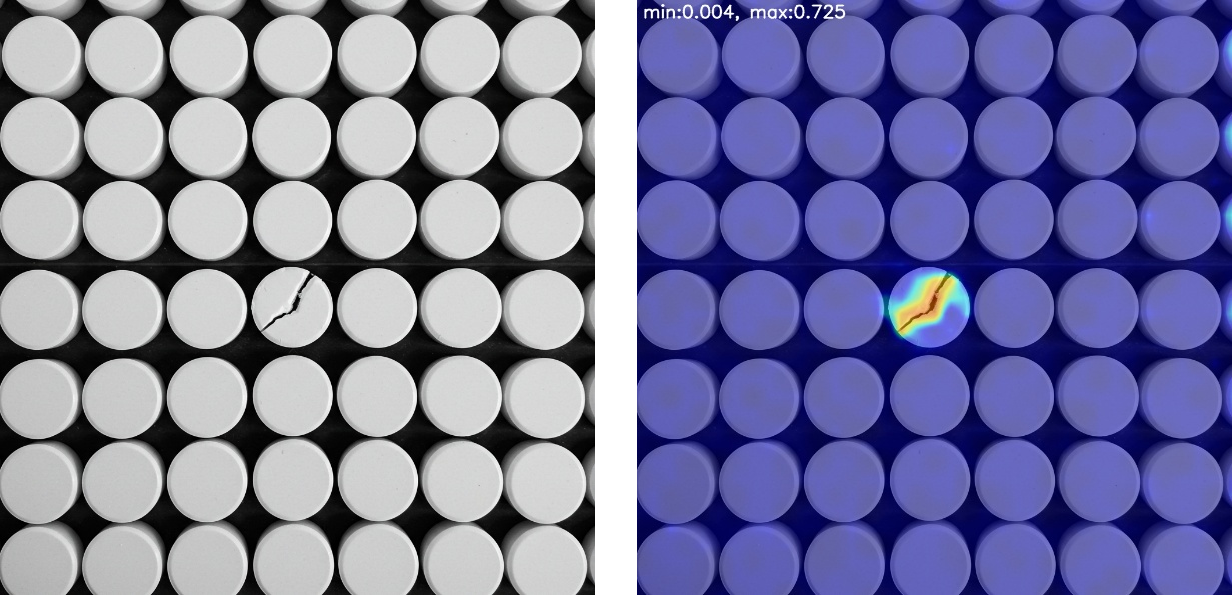

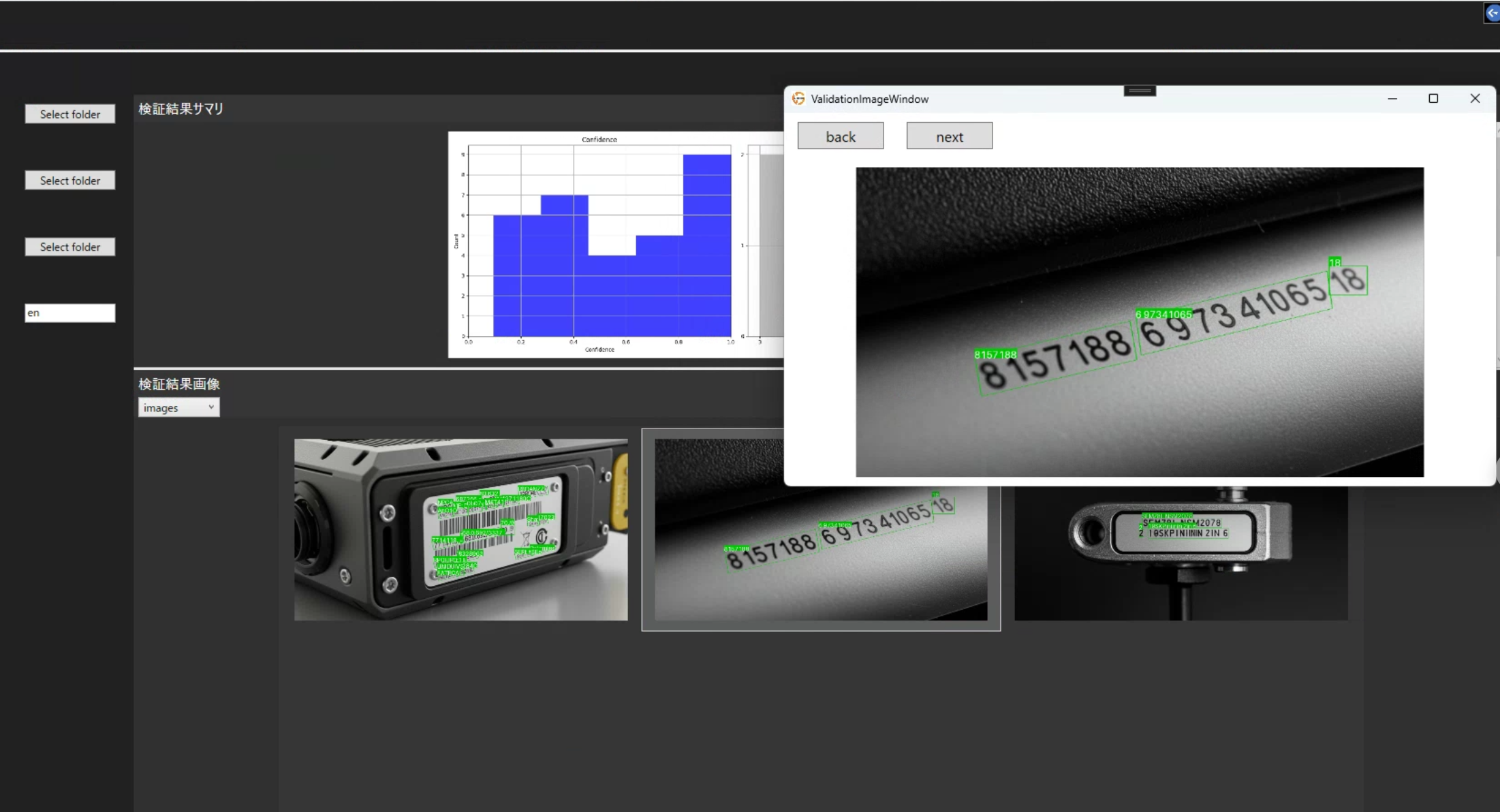

Start inspection immediately without prior image training.

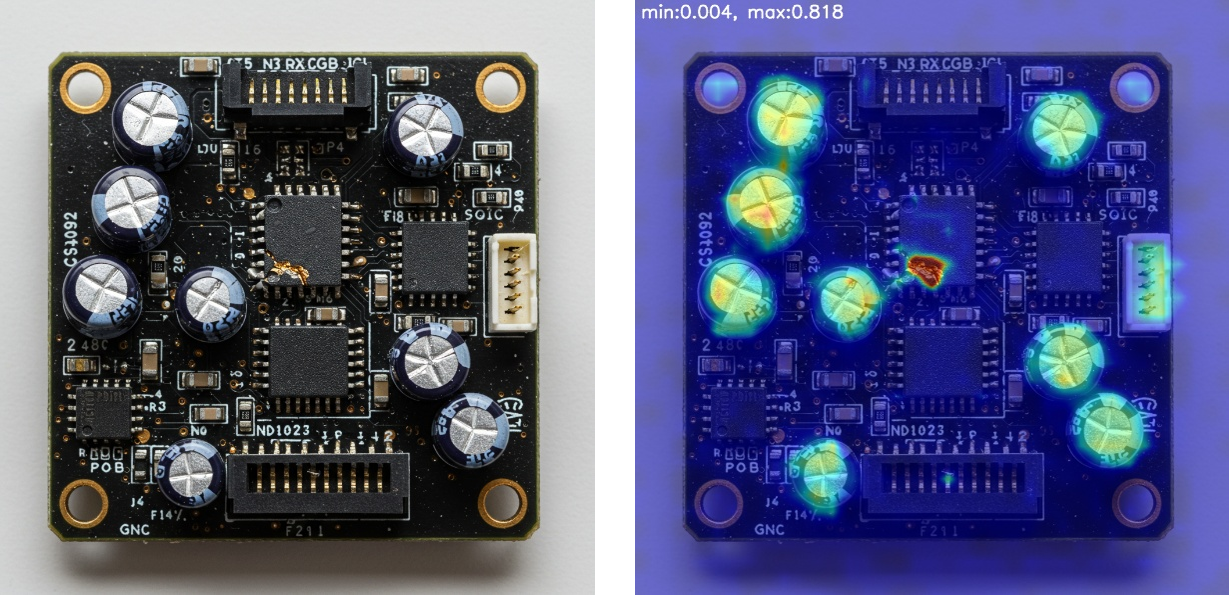

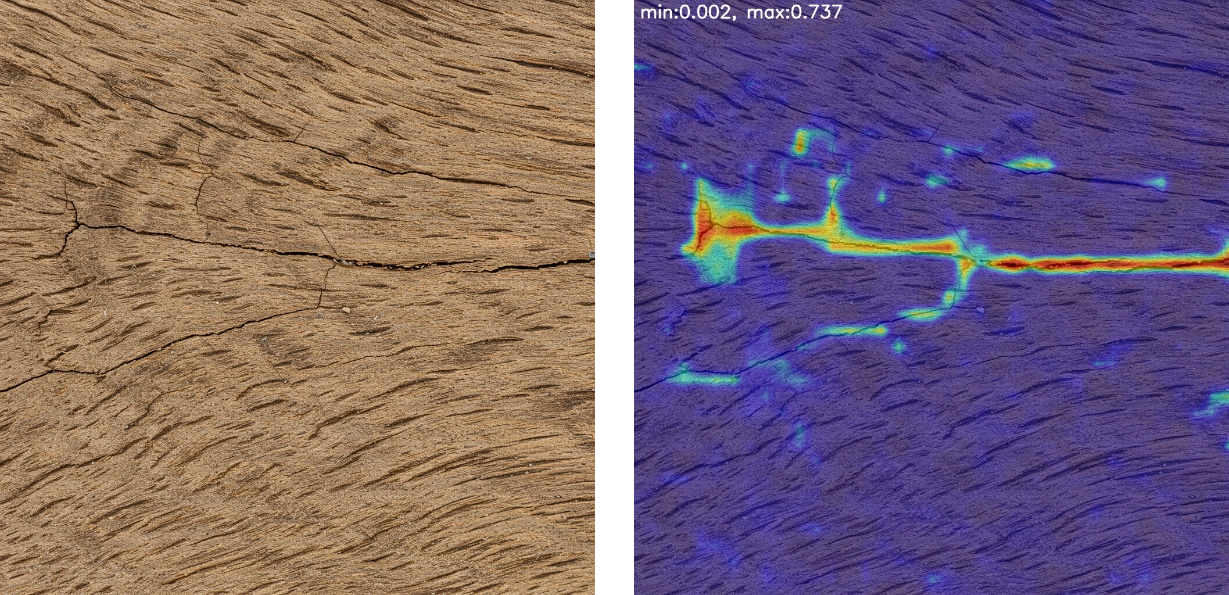

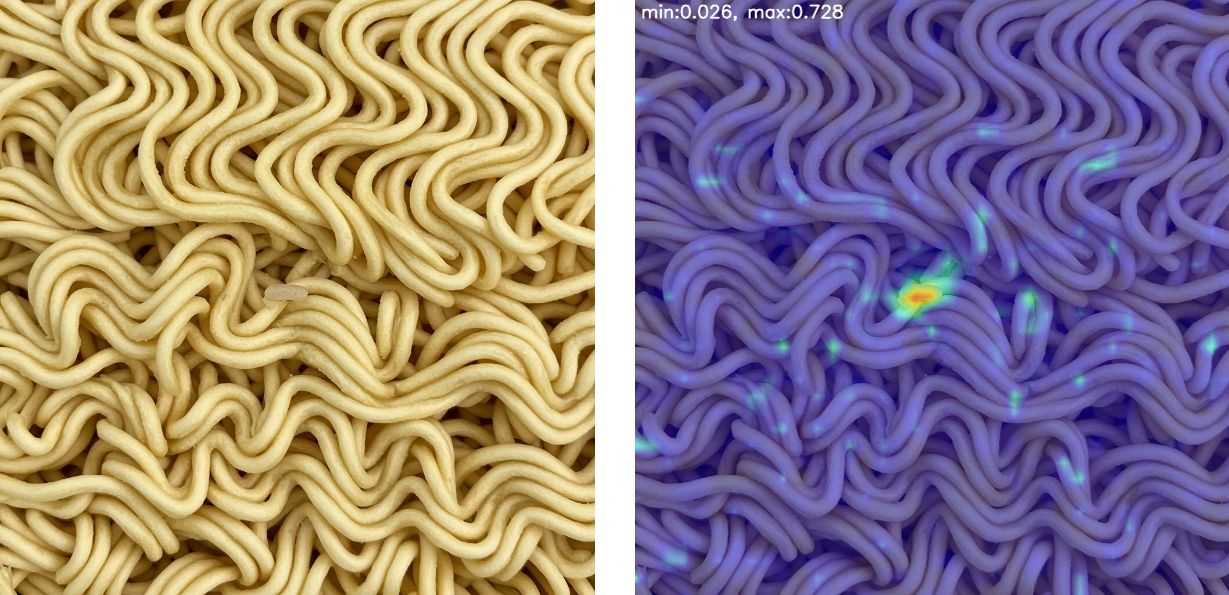

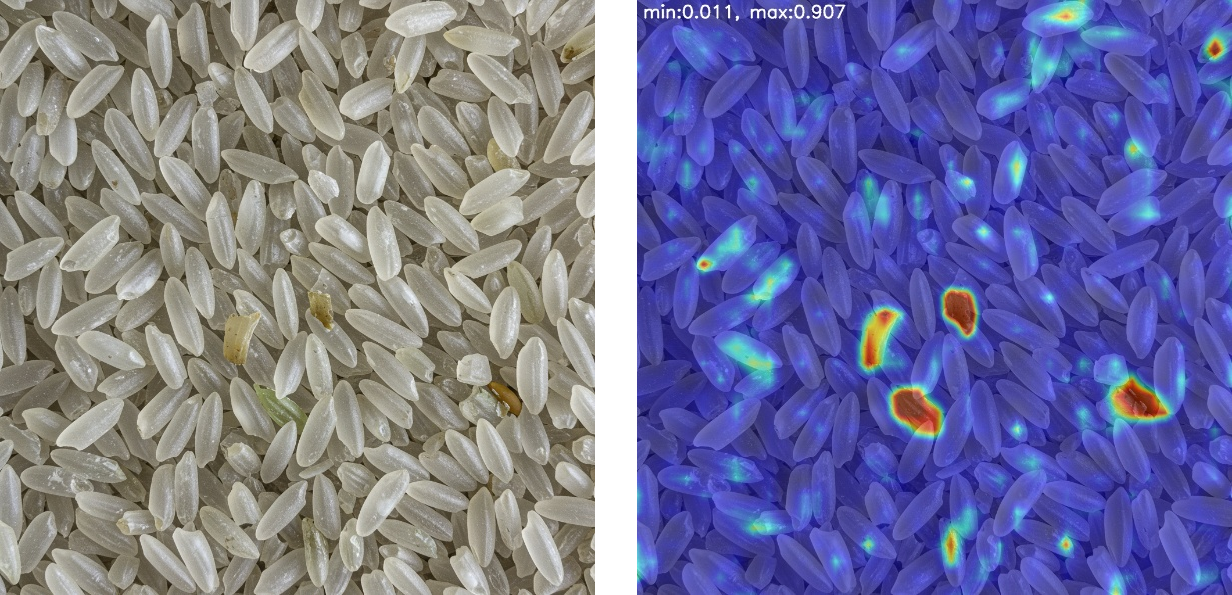

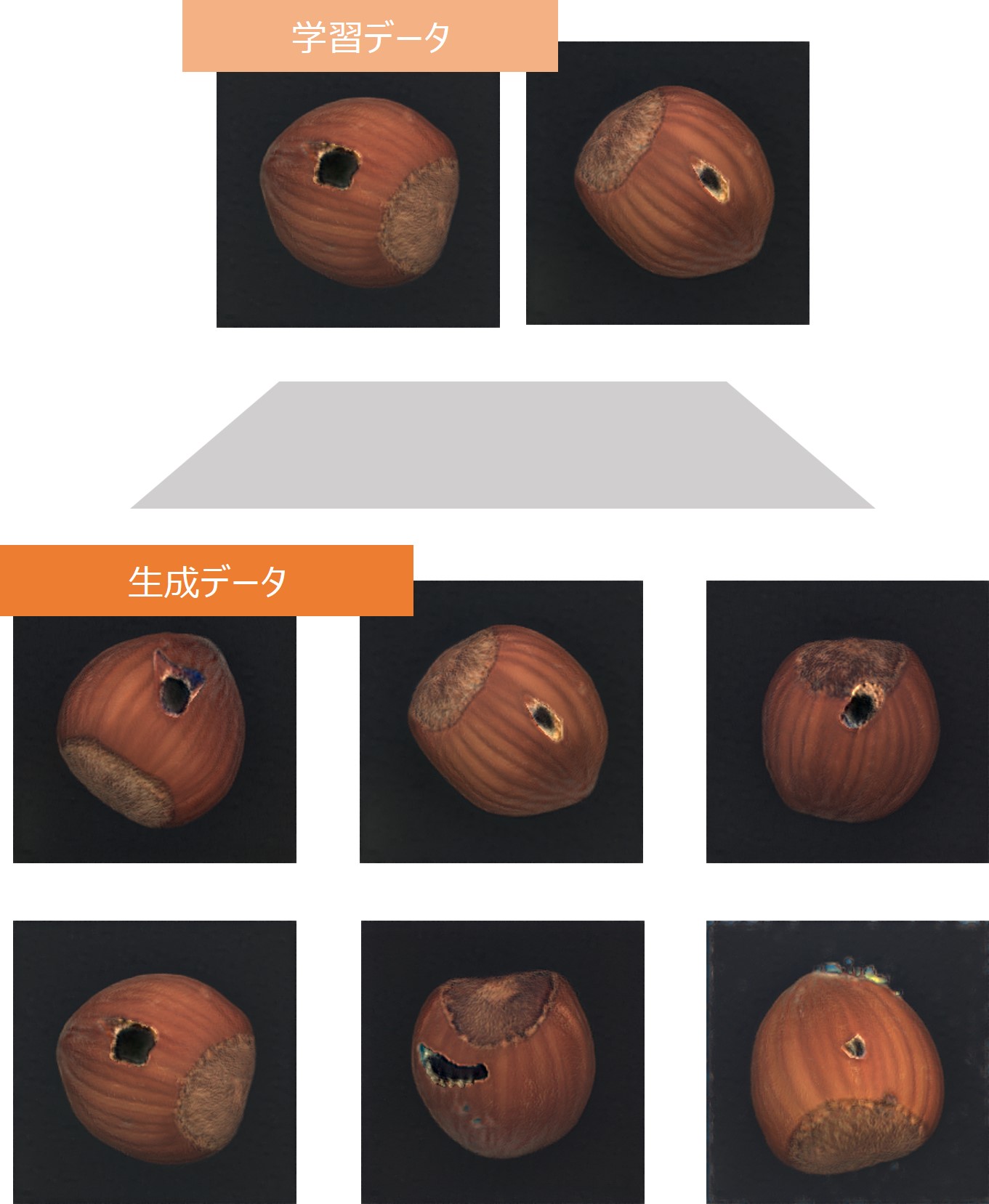

Fine-tuning available. Exceeds existing AI accuracy with just a few images, and can detect unknown defects.

Start without training data collection or annotation

Adjustable for complex targets like food with just a few images

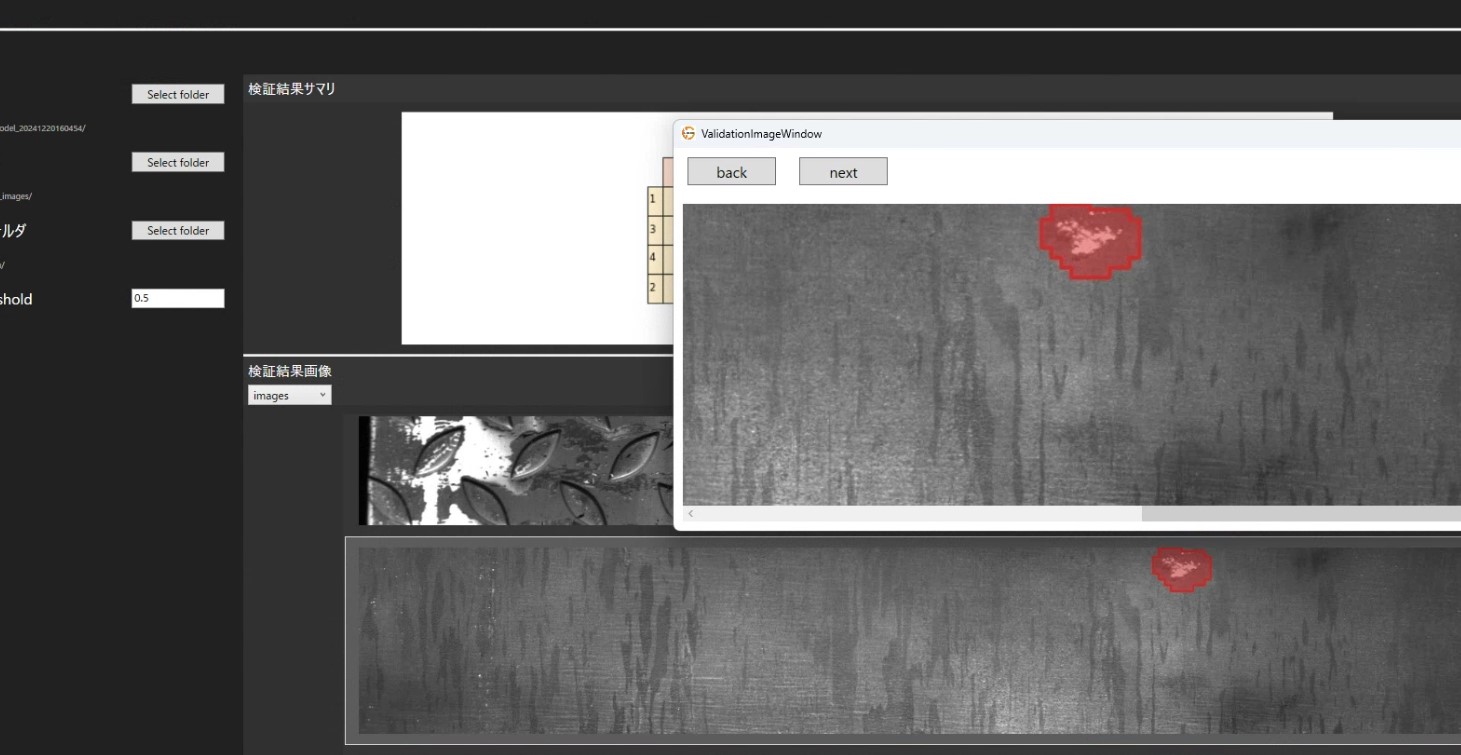

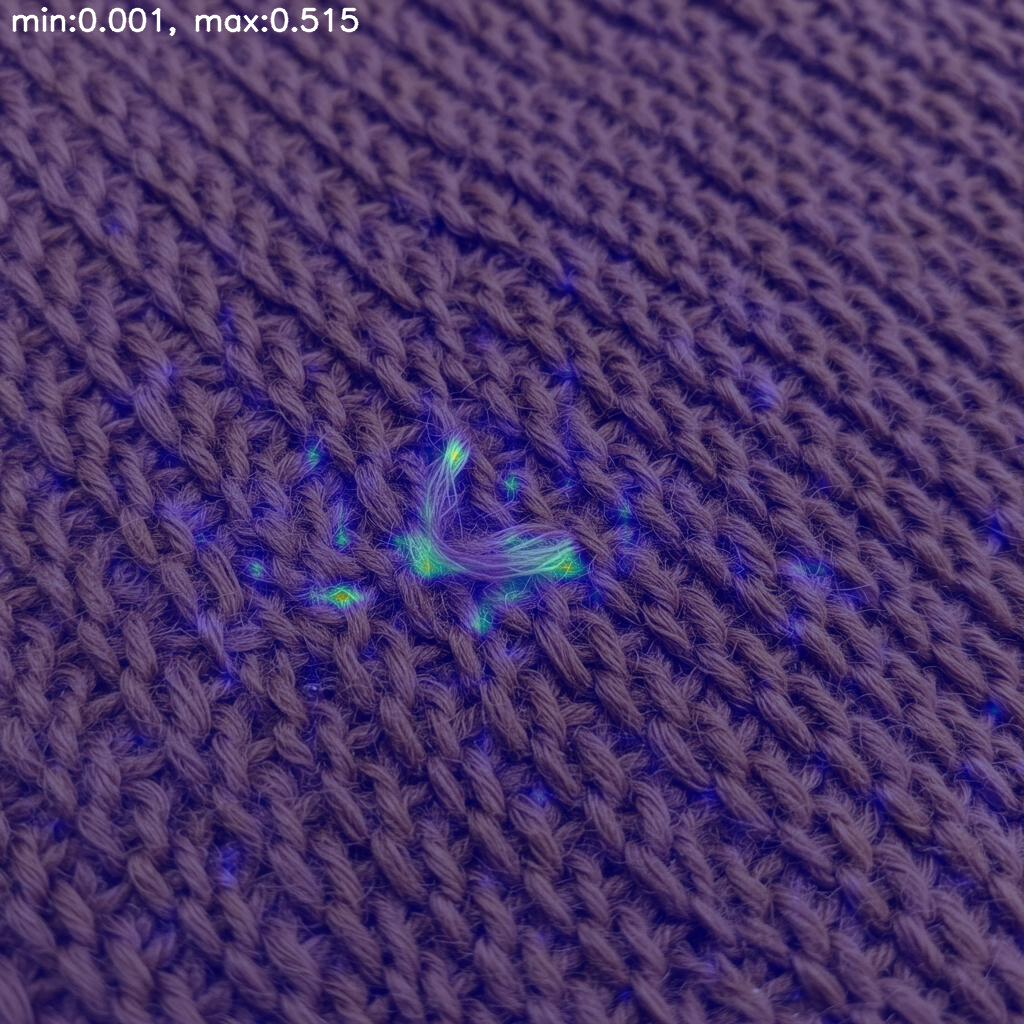

Always capable of detecting unknown defects