Release Overview

OUEN Inc., a venture at the intersection of manufacturing and generative AI, has developed a no-training visual inspection AI,

Zero-Shot Anomaly Detection Generative AI, and has officially released it as part of our no-code visual inspection software

“OUEN Inspection Designer”.

It makes the introduction of visual inspection easier even on production lines with diverse, low-volume production and high variability –

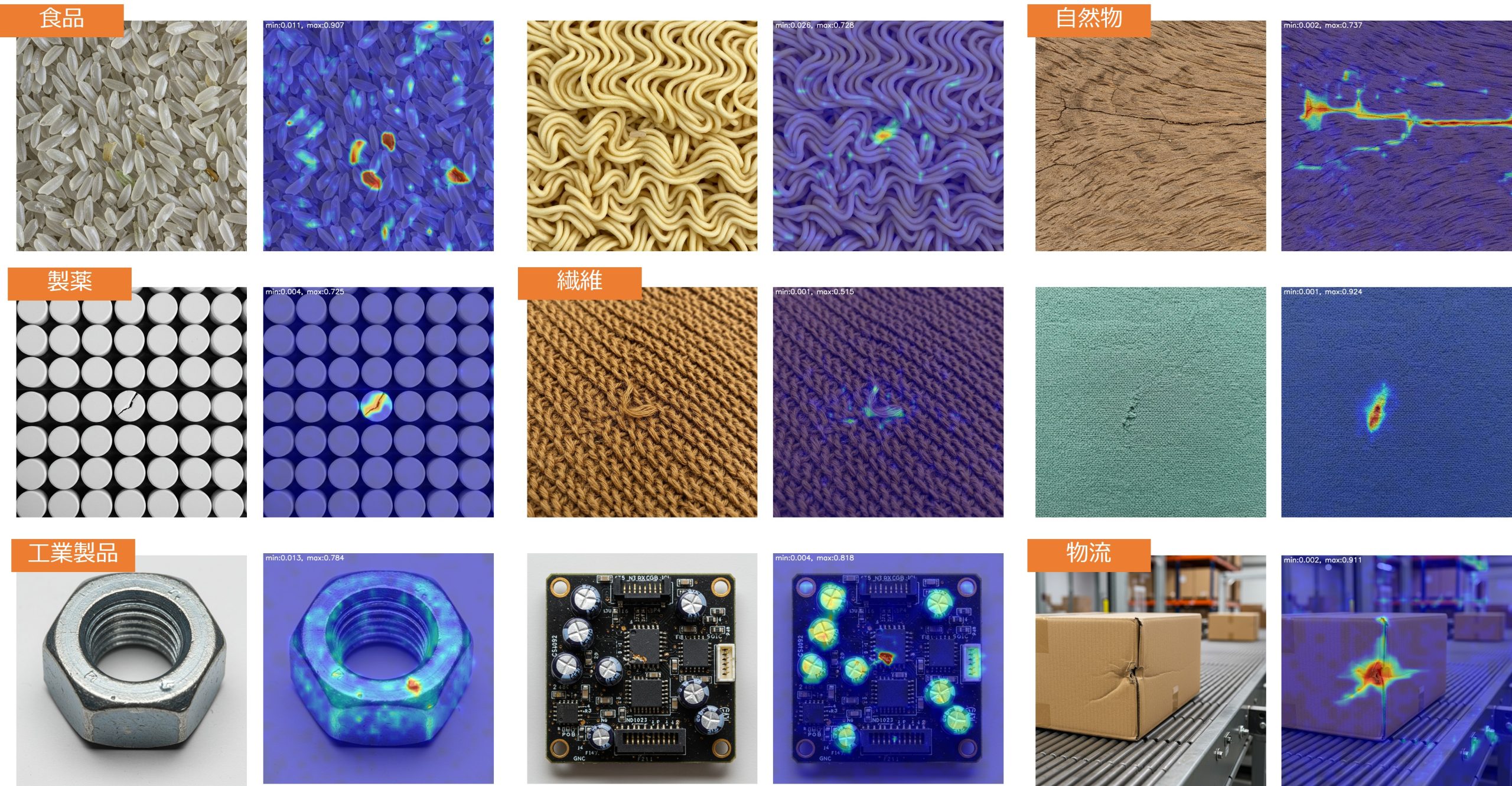

such as in the food, textile, logistics, and material sectors – where traditional image processing and AI have struggled.

Zero-Shot Anomaly Detection Generative AI (hereinafter referred to as Zero-Shot Learning AI) is an innovative technology that enables inspection without any training on images of the target products – a process that traditional AI required either supervised learning (defective product training) or unsupervised learning (good product training/anomaly detection) to achieve.

Our proprietary generative AI excels not only in general object recognition but has also achieved top-level accuracy (pixel AUC above 90 on the MVTec dataset) in research fields, while supporting high-speed inspections (around 100ms per image).

Our company has been at the forefront of product development using generative AI for visual inspection, optimization, and tuning – including our inspection software – and has completed patent filings for the core technology aimed at securing extensive rights.

What is Zero-Shot Learning AI?

Zero-Shot Learning AI (Zero-Shot Anomaly Detection Generative AI) realizes an unprecedented, groundbreaking approach that eliminates the need for prior image training.

It automatically detects defects in products without any training. Not only does it work regardless of camera angle or product type, it also makes judgments that closely mimic human visual perception – even for subtle or ambiguous defects.

Use Cases

It excels not only in diverse, low-volume production lines but also in challenging inspections such as conveyor lines with inconsistent camera angles, as well as inspections of food and natural products.

01 Diverse, Low-Volume Production Lines

In environments where the burden of creating an individual AI model for each product made implementation challenging, Zero-Shot Learning AI eliminates the need for training, allowing inspections to be initiated immediately.

- Food Processing & Inspection

- Apparel & Textile Inspection

- Diverse Production Lines for Machine Parts

02 Lines with Challenging Alignment

While conventional technologies required precise adjustment of orientation and camera angles during conveyance, Zero-Shot Learning AI can detect anomalies without the need for alignment.

- Packaging Inspection in Logistics

- Transporting Loose Items such as Screws and Nuts

- Applications in Incoming and Outgoing Inspections

03 Targets with High Variability (e.g., Food/Natural Products)

When even good products exhibit significant variations in size and shape, conventional AI struggles with training. Zero-Shot Learning AI accurately detects foreign contaminants and defects.

- Inspection for Foreign Objects in Raw Materials and Processed Foods

- Natural Materials such as Wood and Stone

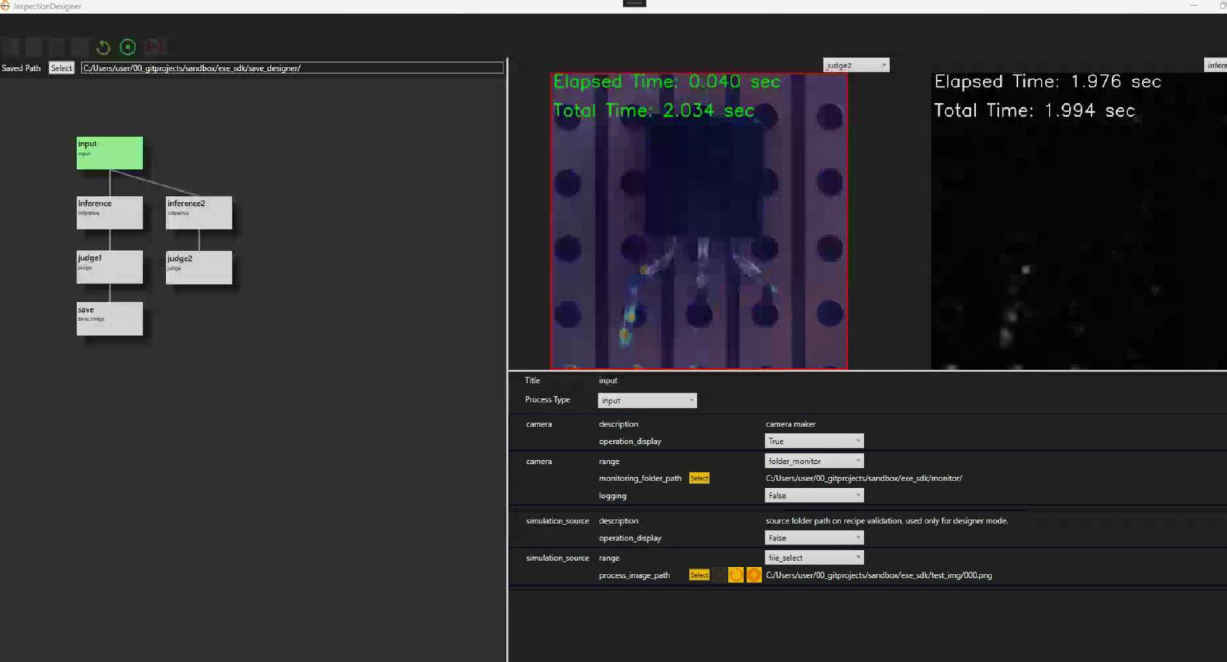

Integration with OUEN Inspection Designer

Zero-Shot Learning AI has been released as a new feature in our no-code visual inspection software,

“OUEN Inspection Designer”.

With a seamless operation from image acquisition to AI inspection, its implementation is extremely smooth.

Request Information & Inquiries

We offer detailed information on Zero-Shot Learning AI and OUEN Inspection Designer, including pricing, case studies, and other materials free of charge.

Please feel free to contact us using the form below.